Build a better now, enable a better future.

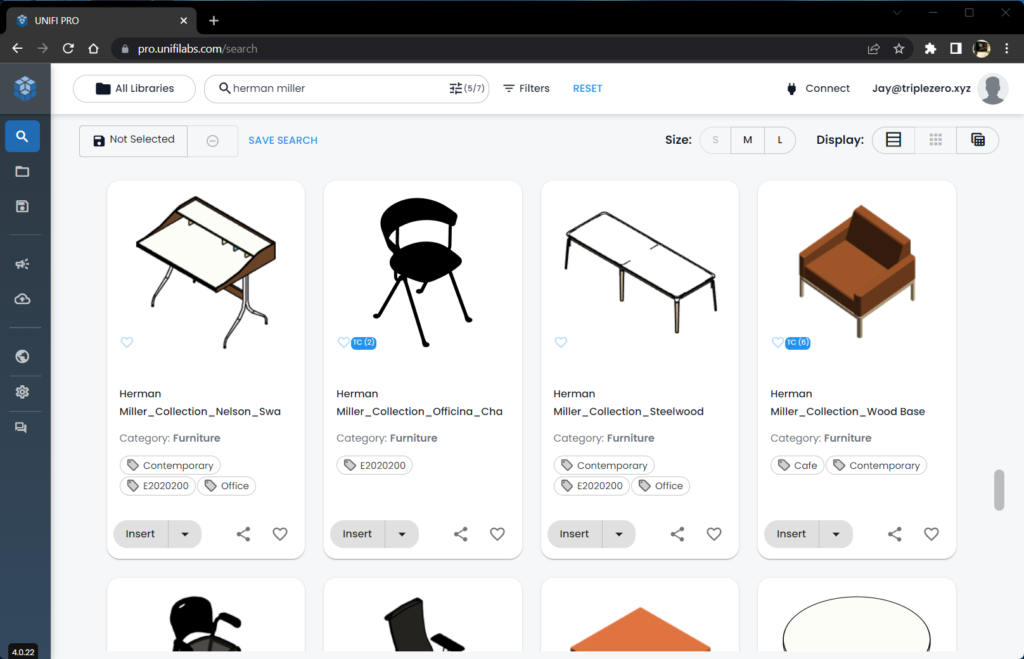

Content Catalog (formerly UNIFI Pro) is a web-based, digital asset management system which leverages BIM data to connect all project stakeholders throughout the building lifecycle and will be available as an entitlement to anyone who has a subscription that includes Autodesk Docs.

A BIM Manager's Favorite Tool

Maintain firm-wide standards by providing remote teams a single source of truth for BIM content via the cloud.

Empowering Designers to Focus on Design

Improve productivity by up to 10x, reducing time wasted manually searching, loading, and troubleshooting models.

Promoting Fluid Data Collaboration

Unlock the ability to read and write BIM data programmatically and autonomously using UNIFI's open APIs.

Higher Quality Models, Faster.

A simplified user experience to find and load quality BIM content which guides teams to produce Better BIM™.

Your Hosted Data, Available Anywhere

Unlimited cloud storage sort BIM content in libraries using meta data, not folders and files.

Enterprise-Level Permissions Control

Robust permission system grants read/write access to internal and external teams.

The AECO Industry's #1 BIM Data Management Platform

Over 40,000 users from leading firms across the globe trust UNIFI.

Frequently Asked Questions

UNIFI is a content management system built specifically for BIM applications and file types. For example, when you store Revit families in UNIFI, it is recognized as a BIM object and users are able to drill down into the RFA file to view family types and parameter data. In other leading cloud platforms, a Revit family is identified as an “unrecognized” file type and doesn’t have the ability to read the underlying data within the file.

According to one customer, UNIFI makes their team 77% faster which equates to saving each designer an average of 2.3 hours per week. Another customer reports their team is able to find content 2x faster than conventional file search methods. Overall, we have seen an efficiency increase by up to 80 hours annually per designer.

UNIFI has a wealth of features which the standard file/folder structures do not provide such as a built-in change management, meta tags, BIM data visibility, and an end-to-end content request mechanism.

While the UNIFI content management system can host virtually any file type, we provide add-ins for most popular design authoring tools such as Revit, AutoCAD, Civil 3D, Bentley, Rhino, and more. This means your library of design assets can be easily loaded from the cloud directly into these applications with the click of a button.

No. Any stakeholder throughout the project lifecycle who interacts with BIM data will find value in the UNIFI platform. The web-based application surfaces valuable program-level and project-level data including asset information, quantities per project (bill of materials), 3D visualization, and more. Additionally, the open API allows more tech-savvy teams to programmatically use BIM data to connecting with other applications and external databases.

Why do I need yet another cloud storage service?

Why do I need yet another cloud storage service?